I do some gas welding and over the years a bench mounted disc grinder/sander has proven to be a great benefit in the shop to not only grind/sand angle iron or box tubing but to grind radius' on stock for ornamental purposes. Since I didn't currently have a bench mounted disc grinder I built one.

Harbor Freight 3/4 hp 8" bench grinder. New $50 plus shipping. $67 total.

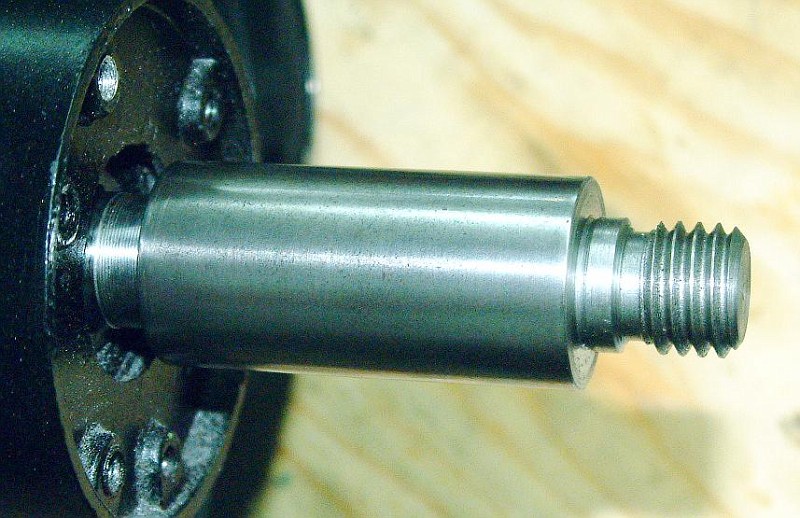

The right-hand shaft threading was cut off.

This is 1" steel stock with the end that mirrors the spindle of disc grinders using a 5/8-11 RH thread and flanged spanner nut.

The table is 1/8" 4140. Just a piece I've had so I used it. The plate the grinder is bolted to is 3/8" x 6" wide mild steel. The legs are angle iron welded together. All the parts so far are bolted together to allow modifications or adjustments. At some point the supporting parts for the table will be arc welded or some of them will be arc welded in place.

The disc is a 7" resin disc normally used on a portable disc sander. This old disc is glued to a piece of 1/2" plywood that's been counter-bored for fit on this shaft. In this way the gritty surface allows better adhesion of new discs installed on top of the plywood backing. I borrowed the flanged spanner nut from my cheapy Harbor Freight 4 1/2" disc grinder as I'll use this more. The rounded radius of the feet were done on this tool.

This tool will also use 4 1/2" grinding discs. It'll eat them up pretty good if you lean into it. I can bog down this 3/4 hp motor but overall it does a fine job and is completely adequate. The left end was left alone and has a 6" wire wheel attached as I use it a lot to de-rust salvaged steel stock.

The new disc sander is C-clamped to the bench to allow use of it anywhere, like outside the shop if necessary. That old Craftsman 1/4 hp grinder was one I bought new when I was 19 (I'm 57). I keep waiting for it to stop working so I can buy a new one but it just keeps running. Its my primary lathe tool grinder. But I do think I'll buy another of the Harbor Freight 3/4 hp grinders and build some nice tool rests and use it for lathe tool grinding. I tried this one out before I took it apart and it does fine on 3/4" lathe bits using quite a bit of force feeding (and water dunking).

The left-side of the Craftsman is a 3M deburring wheel. I also use that end for buffing and did use it for wire wheeling but it was way underpowered for that.

Dutch

|

|

|

Reply With Quote

Reply With Quote